Steel Making Projects

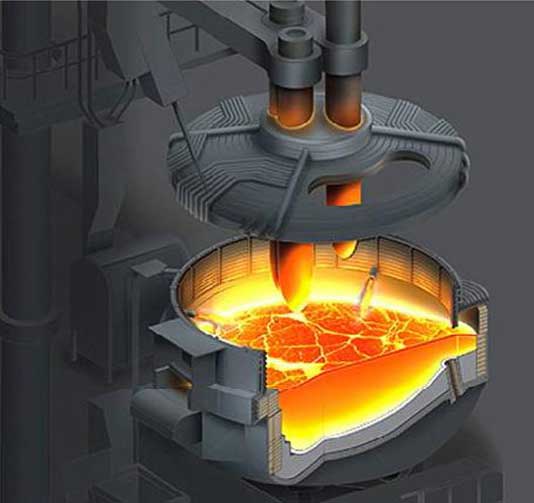

We provide complete technology for setup of modern steelmaking processes, whether primary and secondary steel making.

Steel Making Projects

In this stage, impurities such as phosphorus, sulfur, and excess carbon are removed from the raw iron, and alloying elements such as nickel, manganese, chromium and vanadium are added to produce the specific grade of steel.

The modern Steelmaking process is broadly classified into two categories: primary and secondary steelmaking. Primary steelmaking process uses new iron as the feedstock, usually from a blast furnace. Secondary steelmaking uses scrap steel as the raw material.

- EAF (ELECTRIC ARC FURNACE) - The electric arc furnace offers an alternative method for production of bulk steel.

- BOF (BASIC OXYGEN FURNACE) - This process of steelmaking involves the chemical reduction of iron ore, using an integrated steel manufacturing process or a direct reduction process.

- VACUUM DEGASER - Vacuum degassers are high efficiency inline modules that are basically used to remove the dissolved gases.

- CONTINIOUS CASTER - Continuous Casting Machine (CCM) is revolutionary process equipment used for continuous production of slabs in a single operation.

- ROLLING MILL - Rolling mill forms an integral part of various factories in metalworking industry.

MHL is capable of providing the best kind of support and can facilitate all relevant projects by using its year long expertise in the field.

English

English Chinese

Chinese